Caring for our planet

We aim to achieve netZERO latest by 2050, while driving circularity across our operations.

As a milk processor, our business depends on a healthy environment. That makes it one of the most important areas of action in our sustainability model.

We have therefore set ourselves clear and ambitious targets: we aim to reduce our CO2e footprint at all stages of the value chain, lower our water consumption and reduce waste. We are also working on more circular packaging solutions in order to reduce waste and costs.

Reducing emissions

netZERO 2050 vision

With our netZERO 2050 vision, we are extending our CO2e reduction targets to our entire value chain and moving towards a net-zero pathway. The science-based CO2e reduction targets based on the Science Based Targets initiative (SBTi) are of particular importance here. Our targets were first validated by SBTi in 2021 and are guided by the Paris Climate Agreement.

We recalculated and successfully validated our SBTi targets in 2025. Regular recalculations are an integral part of the SBTi process. The growth of the Emmi Group through acquisitions requires recalculation and revalidation, in addition to sector-specific SBTi requirements. The updated reduction pathway aims to reduce Scope 1 and 2 greenhouse gas (GHG) emissions by 46% by 2031 compared to the 2023 base year. We aim to reduce Scope 3 (non-FLAG) emissions by 46% and are committed to reducing Scope 3 (FLAG) emissions by 33%, both by 2031 and compared to the 2023 base year. These ambitious interim targets are part of our long-term commitment to achieving netZERO by 2050.

We are consistently continuing with our ongoing measures and targeting our resources specifically at projects that make a visible contribution to reducing emissions. To this end, we are revising the decarbonisation roadmap, which identifies potential for reduction across the Group. We are focused in particular on our Scope 3 emissions, which account for more than 98% of our CO2e footprint. To make progress, we are relying on our flagship projects that offer considerable leverage:

- KlimaStaR Milk: an industry initiative to reduce emissions from milk production in Switzerland by 20% by 2027, with savings of 12,000 tonnes of CO2e anticipated annually. In the first two years of the KlimaStaR Milk project (2022–2024), the participating farms were able to reduce their greenhouse gas emissions by an average of 4.9%. The findings of this project are also incorporated into our international sustainability efforts.

- Promoting climate-friendly milk production in our international markets: Brazil and Chile are compiling their databases and planning site-specific measures aimed at reducing emissions. With “LPA Low Carbon”, our Brazilian subsidiary Laticínios Porto Alegre is pursuing the goal of systematically measuring emissions in milk production and reducing them with targeted measures. Initial pilot operations are providing representative data to identify sustainable practices and engage customers.

- Sustainable Swiss Milk industry standard: since February 2024, 100% of our Swiss milk suppliers have been meeting the requirements set by the “Sustainable Swiss Milk” industry standard, and the associated animal welfare and feeding requirements. Despite having achieved its objectives, Emmi continues to play a role in its further development.

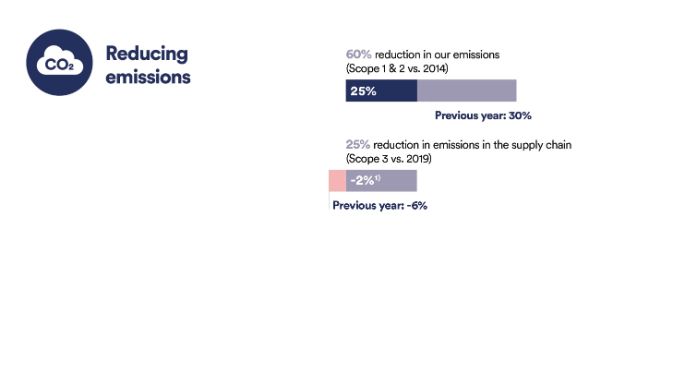

Compared with the base year (2014), we were able to reduce greenhouse gas emissions (Scope 1 and 2) by 25%. However, we recorded an increase of 5% compared with the previous year due to acquisitions. Excluding Emmi Dessert USA (acquisition effect), we would have achieved a reduction of 27% compared with the base year. In the 2024 reporting year, Scope 1 greenhouse gas emissions increased by 8% compared with the previous year (+7,900 tonnes of CO2e). This development is driven primarily by the integration of the subsidiary Emmi Dessert USA and refrigerant losses in Chile. The switch from non-renewable primary energy to renewable biomass in Chile was encouraging, leading to a reduction of around 3,800 tonnes of CO2e in the current year. Further reductions were achieved through energy efficiency measures at the production plants in Bettinehoeve (Netherlands) and Mahdia (Tunisia).

Supply chain (Scope 3) emissions fell by 4% year-on-year in the reporting year. This is due to an improved database for milk volumes in Chile.

> Information on measures and projects to reduce greenhouse gas emissions at our milk suppliers in Switzerland.

1) Fluctuations compared to previous years due to data and calculation adjustments.

Calculations of all key figures: Methodology for non-financial figures 2024.

Reducing waste

We are committed to strengthening the circular economy and want to halve the volume of waste and food waste in our own operations by 2027. The remaining waste may no longer be disposed of in landfills by 2027 at the latest. Our packaging is very important to us and our consumers. We are aiming for 100% recyclability here and using at least 30% recycled material by 2027.

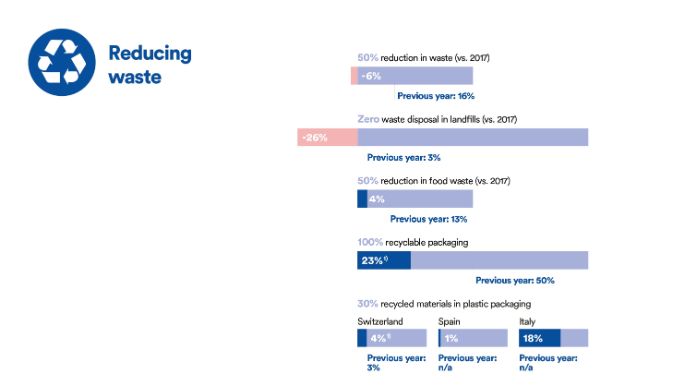

Inorganic waste sent for incineration increased by 19% in absolute terms in 2024 compared to the previous year. Waste disposed of in landfills increased by 31% compared to the previous year. This increase is due to a correction in data collection at the Tunisian plant and changes to local regulations in Brazil. As a result, waste intensity increased from 7.6 kg per tonne of product to 9.6 kg per tonne of product, which corresponds to an increase of 26% compared to the previous year (excluding acquisition effect: +18%).

In the division Europe (Germany, Belgium, Italy, France and Austria), following clarification with the service provider at Pasticceria Quadrifoglio (Italy), the last remaining quantities of waste that were previously disposed of in landfill were diverted to incineration in 2024. This means that no more operational inorganic waste from Emmi’s plants in division Europe is sent to landfill. Emmi has also achieved its target in the division Switzerland.

Although Emmi was able to reduce food waste in Switzerland compared to the base year (-4%), the food waste rate in Switzerland increased by 11% in 2024 compared to the previous year. The main driver of this increase is the growth in cheese production and the associated increase in the quantity of whey as a by-product. In total, 57% of whey was returned to the food channel in 2024 (not considered food waste), while 30% of whey is used as animal feed and 13 % is used in biogas production.

Emmi is constantly looking for new options and partnerships to further utilise by-products such as whey or oat pomace. For example, Emmi is working with various start-ups to develop new products from these by-products.

The proportion of recyclable plastic packaging in Switzerland is 23% (target by 2027: 100%). Compared to 2023, this figure has fallen significantly thanks to a new, more accurate calculation method. The proportion of recycled material is 4% in Switzerland, 18% in Italy and 1% in Spain (target by 2027: 30%).

By constantly switching milk drinks from HPDE bottles to PET bottles, Emmi Switzerland is increasing the recyclability of its packaging, as PET bottles can be collected via PET-Recycling Schweiz (PRS) and managed in a closed loop. With its own PET plant in Ostermundigen, Emmi can achieve a further positive environmental impact: as blanks are inflated to PET bottles on site, less packaging transport is required.

Cheese packaging made from PET material was switched to 100% rPET in 2024. Milk-based drinks that previously consisted of PE bottles were switched to PET bottles. As a result, Emmi can use 25% recycled materials from the cycle of PET-Recycling Schweiz (PRS) for each bottle.

1) Fluctuations compared to previous years due to data and calculation adjustments.

Calculations of all key figures: Methodology for non-financial figures 2024.

Reducing water use

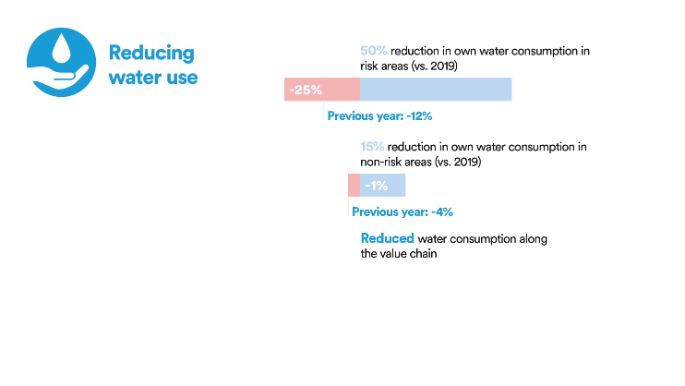

Clean water is an increasingly scarce resource with water scarcity even becoming acute in some regions. This is why we focus on arid risk areas and are committed to reducing fresh water consumption in our facilities by 50% by 2027. In all other countries, we are aiming for a reduction of 15%.

Emmi’s water intensity is currently 1%, or 25% higher than in the base year 2019. One of the reasons for this is the extensive product range, as the many production changes lead to higher cleaning costs despite efficiency measures. There was also a shift in the product range towards products with a higher dry matter content, such as cheese and powder, compared to the base year.

In 2024, the subsidiary Kaiku in Spain continued to optimise its cleaning processes, eliminated leakage points and raised awareness among employees. Thanks to comprehensive cost-saving and optimisation measures, absolute water consumption at the plant in Pamplona was reduced by around 41% compared to the 2019 baseline year.

Calculations of all key figures: Methodology for non-financial figures 2024.